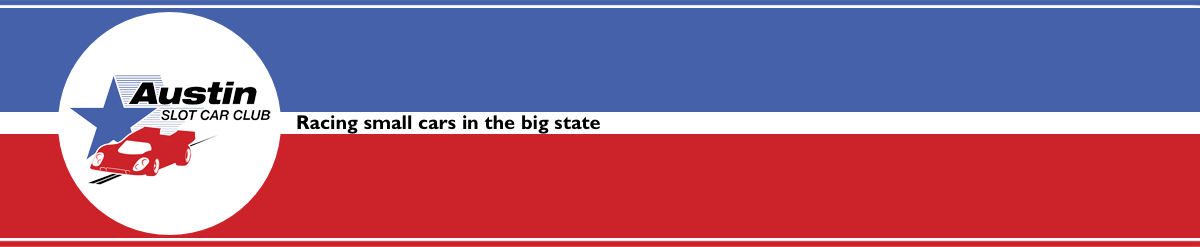

Under the Hood – Marty’s Alfa 155

Marty’s Alfa 155 had a difficult start to the series but the car has steadily improved as the car and tires came good. The car has climbed the leader board from an 8th place finish in the first round to a third place in the second and a second place in the third round with the cooler temperatures. This Alfa 155 is now 4th in the overall standings and although its not the top placed Alfa 155 it is the one that has seen the biggest gain in the overall results. To see what’s going on with this quick Alfa 155 lets take a look “Under the Hood”.

Having a well set up car is not a new thing for Marty as he is usually running at the sharp end of the field for many of the series put on by the Austin Slot Car Club. Let’s dig a little deeper into this car to see if we can learn anything about how Marty sets up his cars to make them so quick.

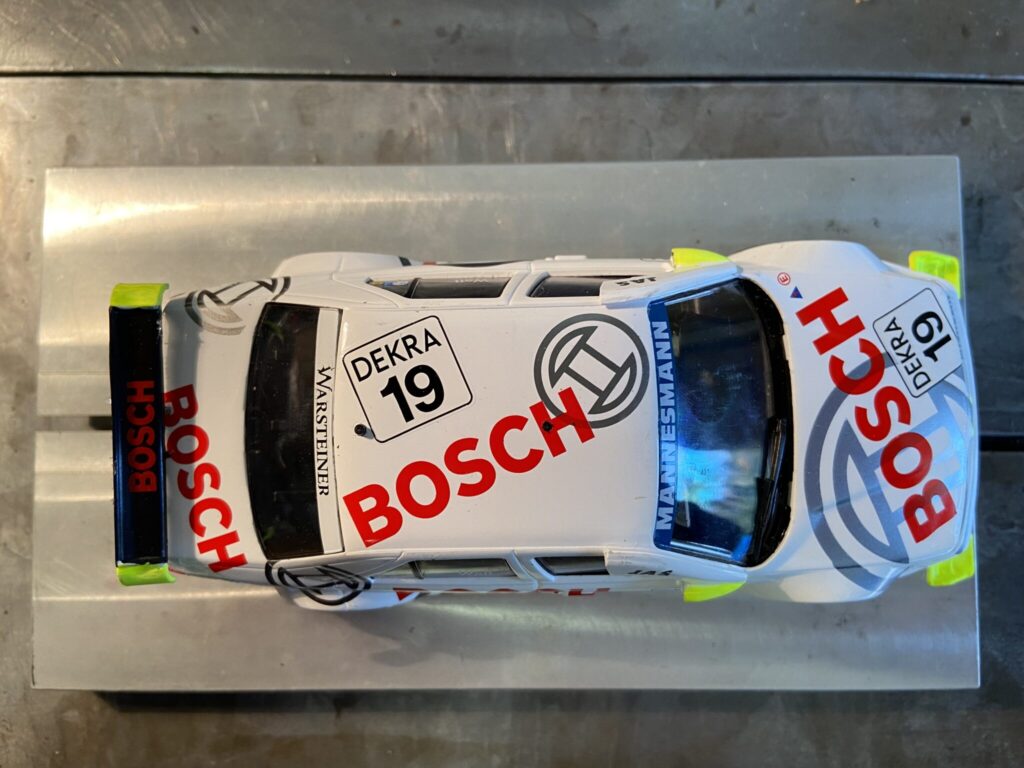

Marty starts every build by striping the car down to every individual part. Once the car is completely taken apart the bare chassis gets placed on a metal surface plate and is baked to make sure it’s as flat and straight as possible before anything is put back on the chassis. This is done to make sure that every adjustment is done to improve the performance and not to make up for any mis-alignment in the chassis.

After baking the chassis, the next step was to rebuild the car using a mix of the stock and non-stock parts to give Marty the feel and performance he’s looking for. The list below shows exactly what parts were used with items in blue being the ones that have been changed from the stock part.

Parts Used

Chassis – Stock, baked

Guide – Slot It wood guide, CH07

Motor Pod – Stock

Motor Pod Bushings – Stock

Pod Screws – Slot It short, large head, CH54

Pod Screw Washers – none

Motor – Stock, with circuit board removed

Motor Fixing Screws – Slot It, CH41

Pinion – Stock, 9t

Crown – 23t aluminum, non-offset

Crown Grub Screw – Slot Car Corner 2mm

Ft Wheels – Slot It Aluminum 15×8, W15808215A, ex PA24-Als

Ft Wheel Grub Screws – Slot Car Corner 2.5mm

Ft Tires – Slot It Zero Grip 19”, PT07

Rr Wheels – Stock

Rr Wheel Grub Screws – Slot Car Corner 2mm

Wheel Inserts – Stock Ft, Black Alfa rear, ShoeGoo’ed in place

Rr Tires – Slot It N22, PT28, glued to the wheels with ShoeGoo

Body Screws – Ft & Rr-Slot It long, large head, CH52

Body Screw Washers – none

Braid – Slot It

Motor Wire – Thin red, hot glued to the chassis

Ft Axle – Stock, 48mm

Rr Axle – Stock, 48mm

Ft Axle Grub Screws-Top – Slot Car Corner oval point, 3mm

Ft Axle Grub Screws-Bottom – Slot Car Corner oval point, 5mm

Ft Axle Holder – none

Ft Axle Spacers – Slot Car Corner plastic combined with brass spacers

Motor Pod Weight – none

Chassis Weight – 7gr located in the center of the chassis right behind the front axle

Car Specs

Weight – 77.4gr

Weight Distribution

Ft – 38.40gr/49.61%

Rr – 39.00gr/50.39%

Height – 42.50mm

Ft Track – 58.85mm

Rr Track – 59.55mm

Wheel RPM – 7,700

Calculated Motor RPM – 19,678@12V

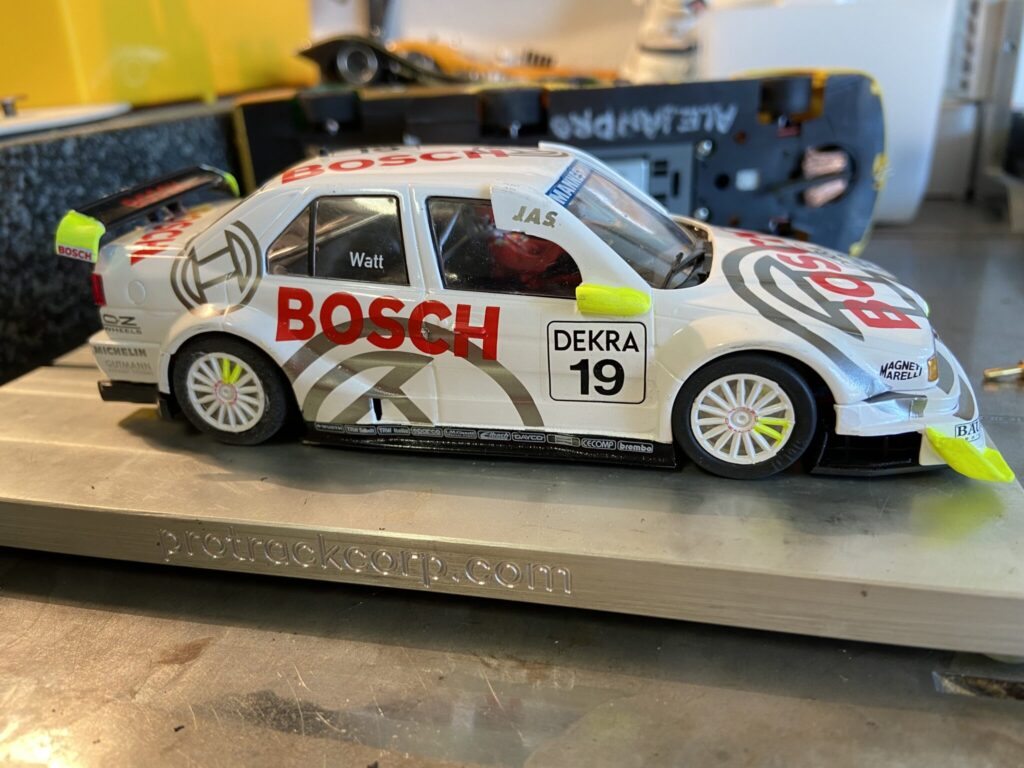

As you can see from the list above there were many things Marty changed on his Alfa 155. The main parts are the stock Slot It parts while the items listed in blue were the ones that were changed. As you can see from the list the items in blue are smaller detail items but they can have a big impact on the final performance of the car – It’s all about the details.

In looking over the list of parts and the work done on the car the item/s we feel had the biggest impact is the use of the F22 tires and having them glued to the wheels. The F22 tires are not the first choice for the Austin track but they can have an advantage in cooler temps and when the track is dusty. The weight distribution is also interesting as it’s the closest to a 50-50 front to back ratio. The combination of the F22 tires, weight distribution with the wide front track make the car stable and easier to drive. It’s not the fastest car but it is stable and just a little easier to drive which equates to fewer de-slots and more laps. One of the other small detail items that Marty did was to ShoeGoo all of the interior and body parts so they would not come lose or rattle around. Having a stable car includes having a stable body with all the parts glued down, including the rear wing. The ShoeGoo under the rear wing adds some support and flexibility to the wing so it resists breaking.

I believe the take away from all of this information is not just the parts Marty used but the attention to every little detail. From baking the chassis to the distribution of weight, to gluing the rear tires to reduce chatter – everything that was done was done with the purpose of making the Alfa the fastest car in the proxy. After three rounds I would have to say Marty did exactly what he set out to do. Congratulations on a great car build.

Marty

Another great article on car setup! Very interesting to compare setup with David’s car. A really excellent write-up.

Russell