Home › Forums › Club Races › Racing Calendar, Classes & Regulations › 2021–NSR Formula 86/89

Tagged: NSR F1 86/89

- This topic has 66 replies, 7 voices, and was last updated 4 years, 3 months ago by

BarkingSpyder.

BarkingSpyder.

-

AuthorPosts

-

July 5, 2021 at 12:33 PM #16689

John – please post a picture of your rollers/rolling-road !

"... get on your bad motor scooter and ride!"

Sammy with MontroseJuly 5, 2021 at 5:17 PM #16690Interested to know what alterations we will be allowed make to forestall failure of the crown gear hub. I replaced my crown with a brass hub NSR piece, because of Aluminum’s propensity for galling.

"Enjoy every sandwich"

-Warren ZevonJuly 6, 2021 at 11:20 AM #16691At this time I would say it is up to the series manager to decide whether or not the Slot It crown gears are allowed. Please post any concerns here so David can review them.

July 6, 2021 at 7:16 PM #16692John

The issue with the stock crowns is the wearing of the channel for the motor shaft, right? (too tight? too binding?) Or is there some issue with the mesh itself? If it is the wearing/friction, then cutting off the end of the motor shaft and adjusting everything tightly, without too much side axle play, would seem the simplest solution. Assuming that would be legal….. I have not had a chance to run my car at all, but that is probably the first thing I would try.

.

July 8, 2021 at 9:52 AM #16695from John: 1st – reference: Post-16688

1 The shallow depth of the NSR crown teeth, presses the motor shaft disproportionately against the Thin (0.50mm) “guard-flange” of the Centering Channel.

2 With the Aluminum shank crowns, the guard-flange wears quickly, shedding AL dust and distorting the shape of the Centering Channel.

3 After less than an hour (on a rolling-road) the crown’s mesh has changed (the teeth are alternatively pressing harder/loser against the pinion). Friction increases noticeably.

4 The NSR brand Brass/Bronze shank crowns take over 45 minutes before they start shedding from wear on the guard-rails. The NSR Brass/Bronze crowns also have a (0.50mm) guard-flange.

5 The Slot.IT brand Brass/Bronze shank crowns have a (0.75mm) guard-flange. After 30 minutes on the rolling-road, the Slot.IT Brass/Bronze crowns seem to have little shed, and NOT degrade in mesh/lash (and hence performance.) The slight eccentricity from the Slot.IT having a larger diameter hole 2.38mm (2.998/32 inch, 0.09370in) vs. 2.37mm (2.9858/32 inch, 0.09331in) for the NSR axle, does Not seem to have any obvious consequences.

6 Russ’ solution to use the OEM brass spacers, and Trim the shaft so that it no longer contacts the Centering Channel – seems to be an easy and viable solution.from Mark:

The wear issue appears to be either a flaw in the Design of the Crown’s teeth (too shallow) or in the Manufacturing during alignment on the Shank (computer parameters mouning the crown on the shank too close to the centering-channel). The skinny 0.50mm Guard-Band also seems like a Doofus design choice with no apparent cost/weight/performance benefit. Note that most NSRs are either short-can pseudo-sidewinders (2deg AW) or long-can angle-winders; so their overall experience with Inlines seems limited (e.g. only ocurrent models with ILs are Mosler, Clio, Abarth, LMP, F1)

In conclusion – I join John in (a) requesting that both (a) the Slot.IT crowns (b) and trimming the motor shaft be Permitted."... get on your bad motor scooter and ride!"

Sammy with MontroseJuly 28, 2021 at 6:36 PM #16772Mark, in 1986/89 from what I can determine, F1 steering wheels looked pretty normal.

Here is a 1988 McLaren cockpit.

[attachment file=”16773″]

Attachments:

"Enjoy every sandwich"

-Warren ZevonJuly 29, 2021 at 3:46 PM #16783Marc – thanks for the technical/historical update : )

"... get on your bad motor scooter and ride!"

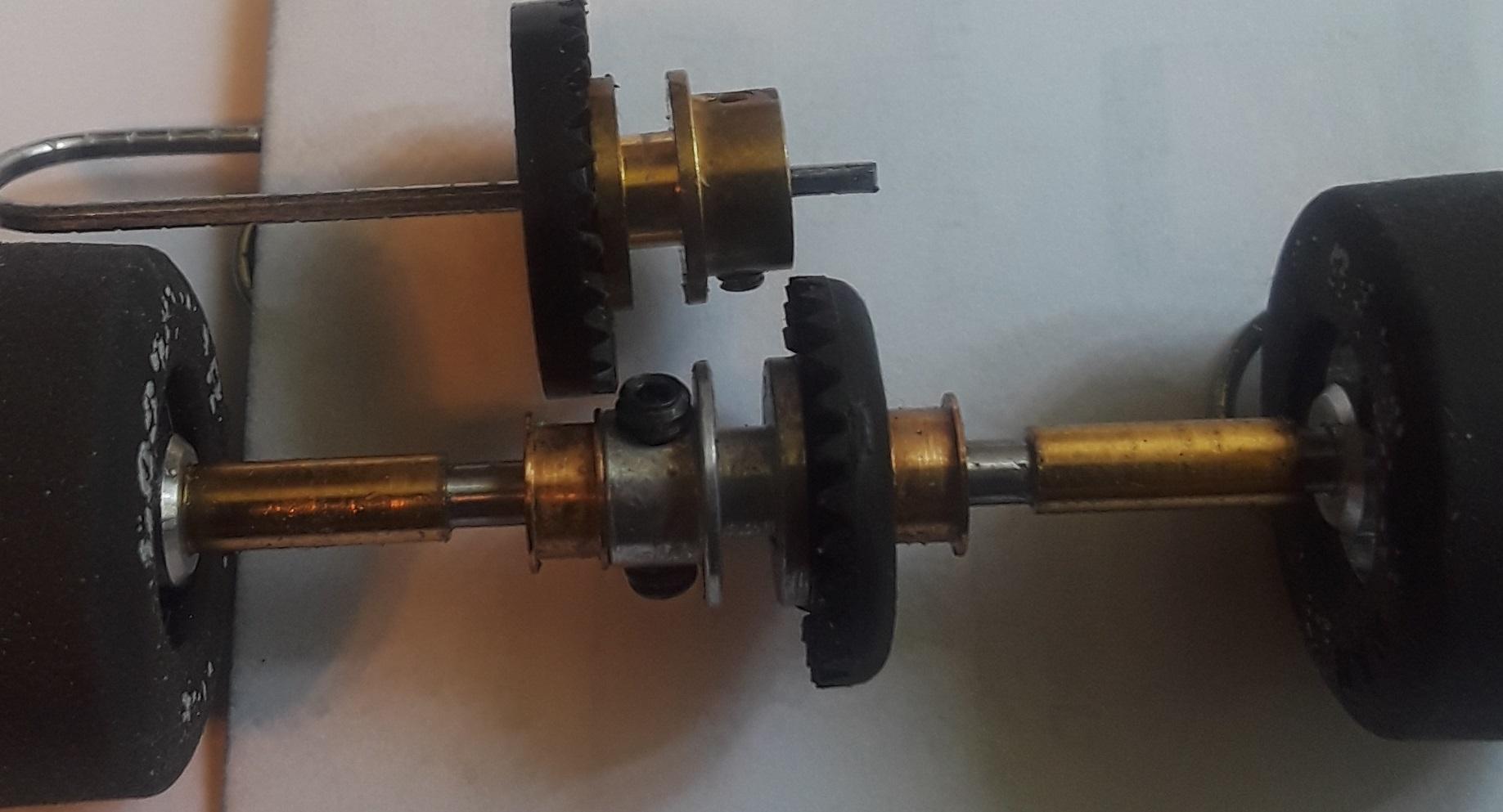

Sammy with MontroseJuly 29, 2021 at 7:39 PM #16788I agree that stop collars can produce more drag, but they are not the only option. Attached is a photo of my Jaguar lightweight that I built four years ago. I am doing some work on it. I originally had two stop collars on it. I put a .005 Slot Car Corner axle spacer, then a .100 axle spacer on the outside of the motor pod, opposite the crown teeth. This limits the axle side play away from a tight gear mesh. The original axle collar is still located behind the crown gear, but it no longer makes contact; the .100 spacer is the limiter. I will probably be removing the collar. Although not totally necessary, I will probably put a spacer on the other end of the axle that will limit the axle play toward tight gear mesh. That way, instead of side load to the crown gear, the side loads will be to the two axle spacers. Once adjusted there will be no more drag than axle spacers. I will see how it works when I have a chance to test it.

Russell

July 29, 2021 at 8:49 PM #16790Nice work Russell. I agree with your assessment of axle collars. I’m going to try running without them to see how it goes.

Marty

July 30, 2021 at 1:37 AM #16796VIDEO OF USING STOP COLLARS AND TRUNCATED MOTOR SHAFT

“This is basically what Russ described, a nice how-to video from NorCal ” Marc/Datto

"... get on your bad motor scooter and ride!"

Sammy with MontroseJuly 30, 2021 at 2:41 AM #16798RUSS – where did you get the 3DP motor pod with adjustable off-set? Is it easy to adjust?

"... get on your bad motor scooter and ride!"

Sammy with MontroseAugust 20, 2021 at 2:57 PM #16836Are we allowed to put nail polish or other compound on the front wheels to lessen the grip?

Marty

August 23, 2021 at 10:24 AM #16841I would like a ruling from the Series Manager. There are now several tire/wheel options from NSR for the F1-86/89.

REAR TIRES:

OEM/original (19.5 X 13) NSR-5284 (Supergrip 25shore?) 5284 (Ultragrip 15~20shore?)

Alternative (19.0 X 13) NSR-5287 (Supergrip) 5288 (Ultragrip)

Both 19.5 and 19 OD fit the NSR F1 wheels with a 13mm Diameter Rim/bead.FRONT TIRES: NSR-5290 (16X8) NSR-5291 (17X10) Zerogrip (fit the same wheel-5020)

WHEELS

REAR OEM NSR-5021 have an “air-system” Rib/Nib. 13mm OD x 10mm width

NSR-5027 – Solid Rib/Nib. 13mm OD x 10mm width

NSR-5022 -“air-system” 13mm OD x 13mm width

NSR-5026 -“air-system” Drilled – 13mm OD x 13mm widthFRONT OEM NSR-5020 solid Rib/Nib. 13mm OD x 8mm width

"... get on your bad motor scooter and ride!"

Sammy with MontroseAugust 24, 2021 at 1:40 PM #16857I would suggest keeping the rules for the cars as stock as possible. I don’t see a need to upgrade or change wheels or tires as the stock ones work well. This will also help keep costs down.

Having said that, the crown gear could be another conversation.

August 25, 2021 at 12:38 AM #16866GEAR RATIO CHOICES WITH THE AVAILABLE CROWNS: 27z 25z 24z

The calculated rear-wheel-RPM – OEM @12volts: OEM ratio 21,400/(27/10)

= 21,400/2.7 > 7,926 **Other Gear Options: @12volts

24/9 = 2.67 > 8,015 **

25/9 = 2.78 > 7,698

// not really usable at 12v

…27/9 = 3.00 > 7,134; …25/10 = 2.50 > 8,560; …24/10 = 2.40 > 8,917@11volts OEM ratio 27/10 = 21,400(11/12)/2.7 = 19,617/2.7 > 7,265

24/10 = 2.40 = 8,174 **

25/10 = 2.50 = 7,847 **

…24/9 = 2.67 > 7,347; …25/9 = 2.78 > 7,056; …27/9 = 3.00 > 6,539SPARES

OEM NSR 6327AL 27 tooth black crown, Aluminum shank

NSR 6324BR – bronze/brass shank

NSR 6325BR

NSR 6327BROEM NSR 7010-10 tooth “easy” pinion. 5.5mm OD

NSR 7009-9 9 tooth

NSR 6809-9 Lightweight

NSR 6809-10 Lightweight"... get on your bad motor scooter and ride!"

Sammy with Montrose -

AuthorPosts

- You must be logged in to reply to this topic.